HOME > Packaging, OCC & Paper Board

HOME > Packaging, OCC & Paper Board

Service hotline +86 18613966565

Packaging paper high consistency refining:

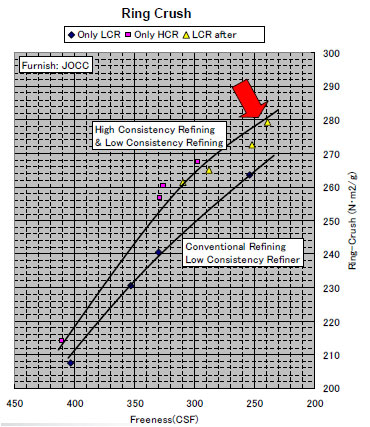

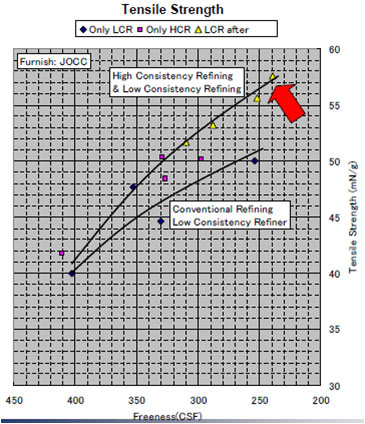

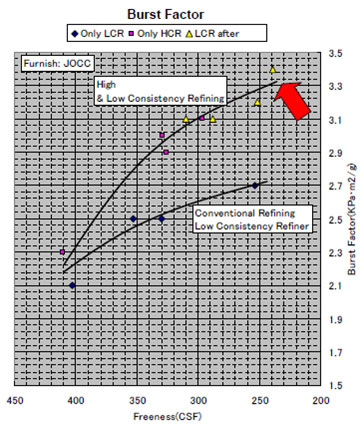

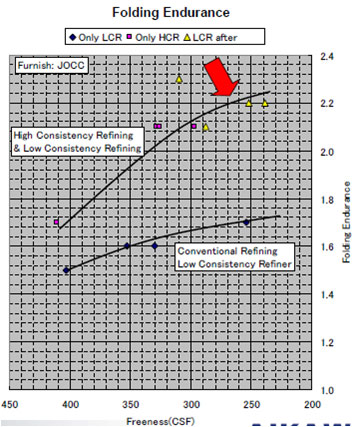

For treating waste paper pulp, the high consistency refining system can significantly increase burst strength and folding endurance, and enhance internal bonding strength. Packaging paper uses recycled waste paper as raw

material has problems of difficult to guarantee the strength performance

indicators including folding resistance, burst resistance, ring pressure, etc.

In large-scale production, it is necessary to add higher-priced high-quality

fibers and reinforced chemical materials. To ensure the required strength of

the paper, the cost increases and the water treatment system is more difficult

to deal with. The high-consistency refining system provided by Genda can solve

this problem. We have cooperated with many customers and have completed the

construction and renovation of more than 30 production lines. Our solution

covers various needs of customers: innovative technology, reliability and

operability, advanced automation solutions and general contract engineering

services, to ensure our client improve paper performance and reduce operating

costs while maintaining smooth operation.

1. Process technology

The advantages of high-consistency Refining

applied to packaging paper:

2. Solution

Image: Process Design Drawing Engineering site work photos

We always maintaining close cooperation with customers, so that we can develop targeted products and processes according to the characteristics of raw materials and paper grades, to meet the needs of customers in terms of product improvement or cost reduction. We provide a package of solutions including process design, equipment selection and supply, advanced process control system with one-key connection with upper and downstream equipment, guided installation services, and general contract engineering services.

3. High-valued customer project case

Case study 1

Picture: High Consistency refining Reconstruction Project of Sun Paper Containerboard machine No. 31, 32, 35, 36

Time and place: 2018 Sun Paper Shandong Yanzhou

Paper machine: Voith Paper board machine with an annual output of 600,000 tons

Customer Project Requirement: stable folding resistance, improved bursting resistance

Genda Solution: Two sets of Genda HCR1100 high-consistency Refining system

Implementation results: The folding endurance of the containerboard paper is stabilized (especially in winter), and the bursting resistance is increased by 20%

Case study 2

Picture: Hengshan Xinjinlong core-board paper low-consistency refining transformation case (two sets high-consistency refining system)

Case Study:

Time and Location: 2020 Hunan Hengshan Xinjinlong Paper Co., Ltd.

Paper machine: 4800 single fourdrinier multi-cylinder paper machine

Customer Project Requirement: Quality Improvement

Genda Solution: Two sets of HCR1100 high-consistency refining system

Implementation results: The product quality has reached B-level standard from C-level. Paper appearance quality is obviously improved, mainly due to the reduction of pulp point and dust point; the bonding strength between layers is increased by more than 100J, and the ring compressive strength is increased by 20%.