HOME > CTMP, Mechanical & Semi-Chemical Pulping line

HOME > CTMP, Mechanical & Semi-Chemical Pulping line

Service hotline +86 18613966565

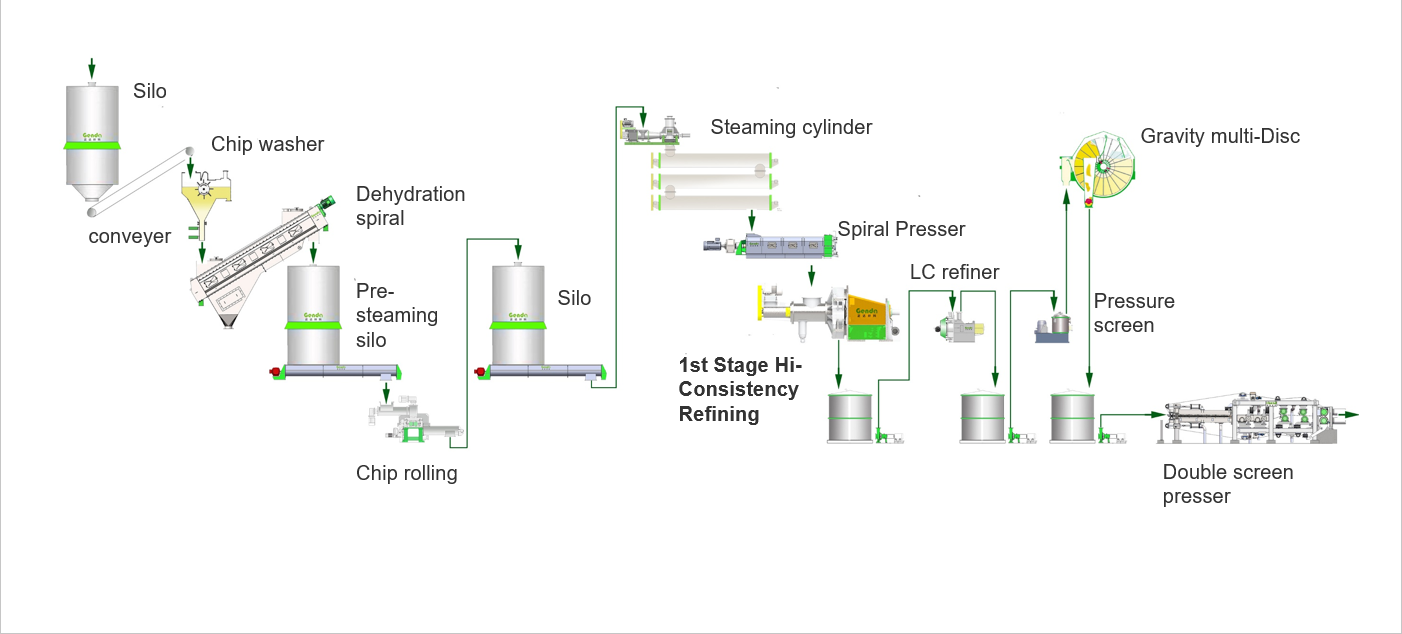

CTMP, Mechanical & Semi-Chemical Pulping line

Technologies, applications and services for high-consistency refining of various raw materials

Regarding the current shortage of packaging paper raw materials in China due to the ban on waste import, Genda has a unique insight into the current Chinese chemical mechanical pulp market. We have developed processes for large and medium-scaled customers with different raw materials, and launched se-ctmp (energy-saving chemical mechanical pulping) solutions, including high-temperature and High pressure-type high-consistency refining solutions and normal-temperature and normal-pressure high-consistency refining solutions. We provide our customers with sophisticated process consulting. At the same time, we have a series of high-consistency refiners, such as normal pressue high-consistency refiner, High-pressure high-consistency refiner, Dual-Drum thickeners, pressing screws, high-dryness double-screen pulpers and other extrusion equipment, dewatering screws, conveying screws, etc. Genda can provide mature and high-quality products for chemical-mechanical pulp fiber production.

1. Process Technology

2. Solution

We maintaining close cooperation with customers, so that we can provide targeted chemical-mechanical pulping process technology routes and high-consistency refining process solutions according to the characteristics of different customers' raw materials and pulp varieties, so as to meet customers' production of high-quality pulp requirement. We provide a package of solutions including process design, equipment selection and supply, advanced process control system with one-key connection with upper and downstream equipment, guided installation services, and general contract engineering services.

3. High-valued customer project case

Picture: Sun Paper's Semi-Chemomechanical Pulp High Consistency Refining Equipment Project Case

Case Study

Time and Location: 2018 Shandong Yanzhou Sun Paper

Paper machine: Equipped with a 6.6-meter board paper machine with a speed of 1,200 meters for the production of boxboard paper

Customer requirement: reduce long fiber usage ratio

Solution: Genda HHR1300 High Consistency Refiner

Raw material: miscellaneous wood

Implementation results: 300 tons per day, met quality standard.