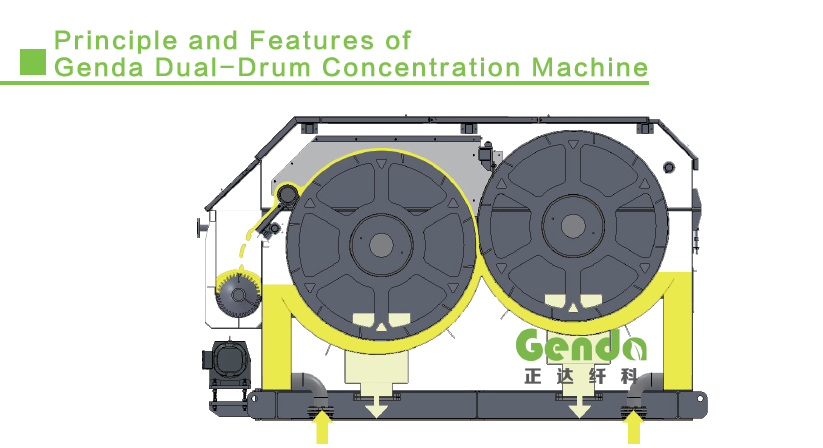

During

operation, pulp concentration of 4-6% enters the drum from two pulp inlets, and

the height of the inlet liquid surface does not exceed the radius of the

circular mesh drum.

The

pulp inlet flow rate is consistent. Start the main motor, and the driving mesh

drum and the driven circular mesh cage rotate in opposite directions

synchronously.

Since

the water outlet is set below the main shaft of the mesh drum, the water level inside

the drum is low, so after the pulp enters the inside of the drum, a part of the

liquid enters the mesh from outside by itself due to the existence of pressure

difference and gravity, to achieve the effect of initial concentration.

Pulp

continues to enter the pressing area upwards. After being squeezed by the two

circular mesh drum, most of the liquid enters the drum. Pressed concentrated

pulp is stick to the outside of the drum, then transfer to driving drum and

delivered outside.

The structure is a simplified version of the twin-roll press, more cost effective;

Small footprint, good sealing, better on-site integration;

Simple structure, 0 maintenance, low energy consumption, energy consumption per ton of pulp is 3 kWh;

Stainless steel mesh, service interval can reach more than 2 years;