The refining process is recognized as the "heart" of the papermaking process. Fiber binding properties, paper strength, and other properties which depend on the quality of the pulp produced by the refining process. One of the important elements that determines the refining

effect is to choose the right plates. For the same refining strength and refining energy, different tooth shapes will result different fiber treatment effects.

No-Hollow Grinding Plates invented by Genda are specially developed for medium or high consistency pulp. Genda specially developed a series of tooth shapes for medium and high consistency

refining to adapt to different pulps.

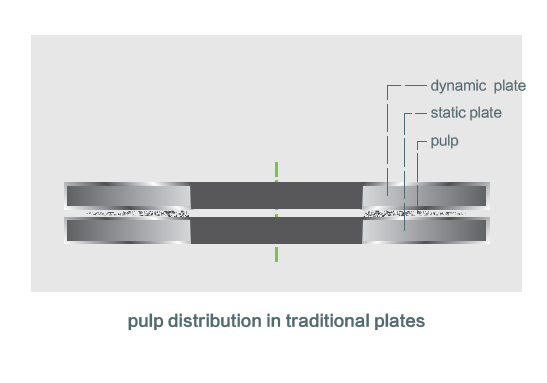

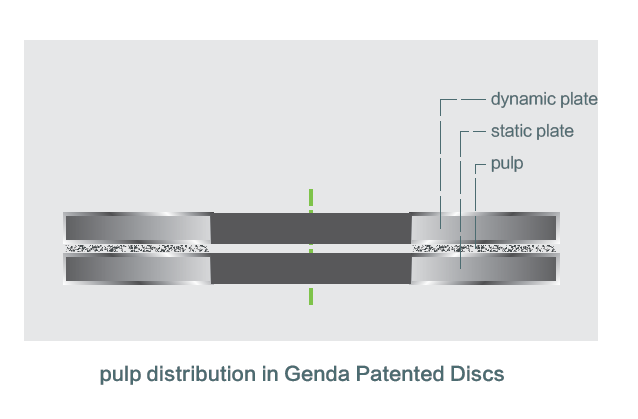

The No-Hollow Grinding Theory refers to the research conclusions of an empty grinding phenomenon due to the different thicknesses of the surface layer of conventional grinding plates.

The non-hollow grinding plate improves the structure of normal plate and make the same thickness of pulp between plates. It can increase the efficiency of grinding up to 20-40%. As no overcutting of the fibers, it can reduce the loss of fiber, increase the yield of pulp and enhance the tension of paper. With this innovative and patented plate, pulp can get 8-12times cutting in one machine, and its freeness being increased by one machine is much higher. Moreover, the flow of pulp and its uniformity are improved a lot. We design the obtuse-angle grinding and “pumping-out” devil tooth especially for the high consistency grinding plate. At last, our patented plate has good performance in its service life and environment protection.

1. Raw material: hardwood, softwood, bamboo, straw, reed, tobacco, waste paper, etc.

2. Pulp: chemical pulp, semi-chemical pulp, chemical-mechanical pulp, mechanical pulp, etc.

3. Paper: corrugated packaging paper, board paper, sulfate paper, printing & writing paper, tissue paper, etc.