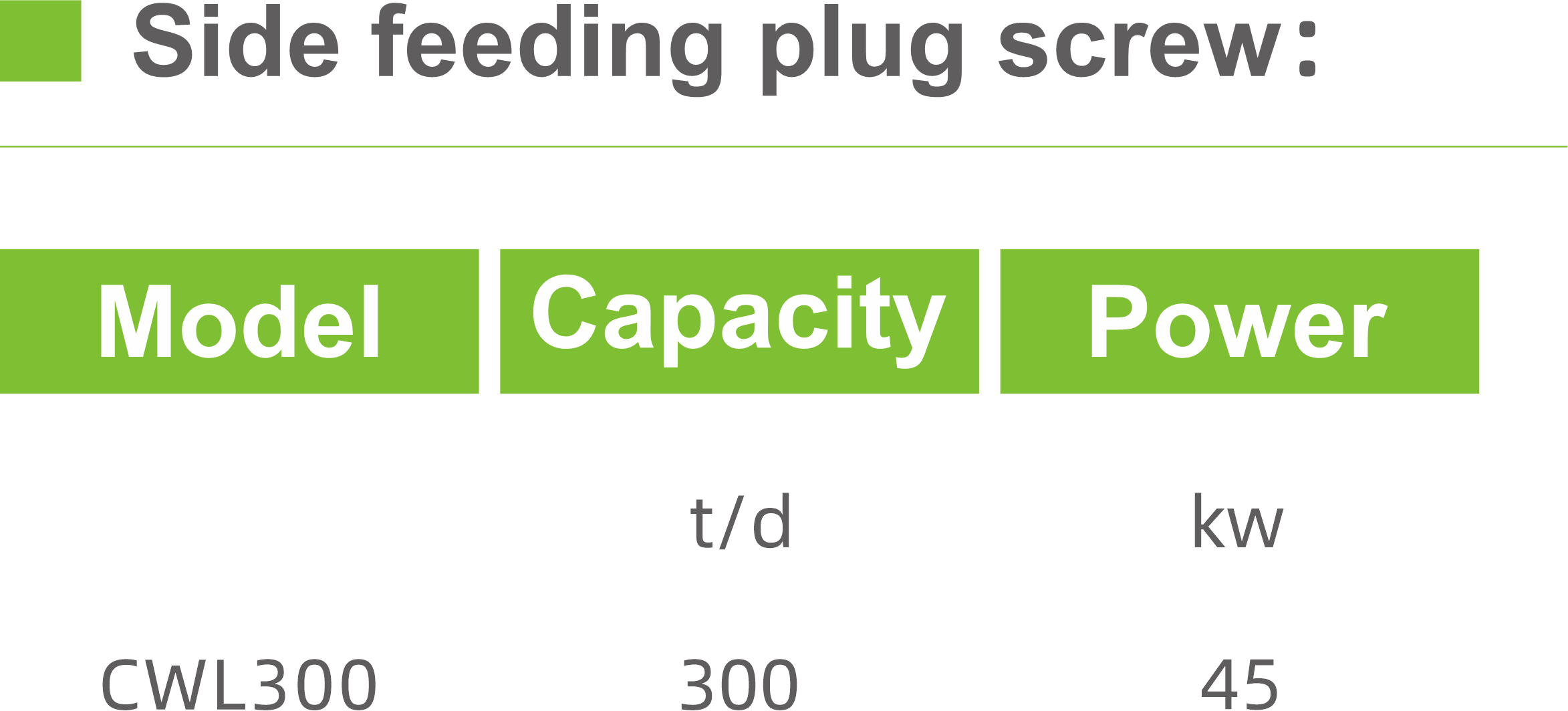

The Plug Screw Feeder forms a plug for the incoming material to prevent the back spray of steam, and forms a pressure system with the refiner.

The Plug Screw Feeder adopts frequency conversion speed control, and the rotation speed of the plug screw is adjusted according to the production capacity to ensure uniform feeding to the high-consistency refiner.

The shell of the Plug Screw Feeder is conical, the inlet end is the big end, the outlet end is the small end, and has a certain compression ratio. When the wood chips are conveyed by the plug screw, they are compressed in the conical part to form a plug, which prevents the steam in the first stage of the refiner from being discharged from the feed port, so that the first stage of the refiner operates under pressure and will not lose steam.

In order to discharge the residual liquid in time during the compression process and prevent the spiral/screw from slipping, there are openings on the cone shell. The spiral is equipped with a cleaning nozzle for easy cleaning.