Traditional CTMP: Energy consumption/ton>1600kw

Traditional PRC-APMP: Energy consumption/ton >1200kw

se-CTMP: Energy consumption/ton <800kw

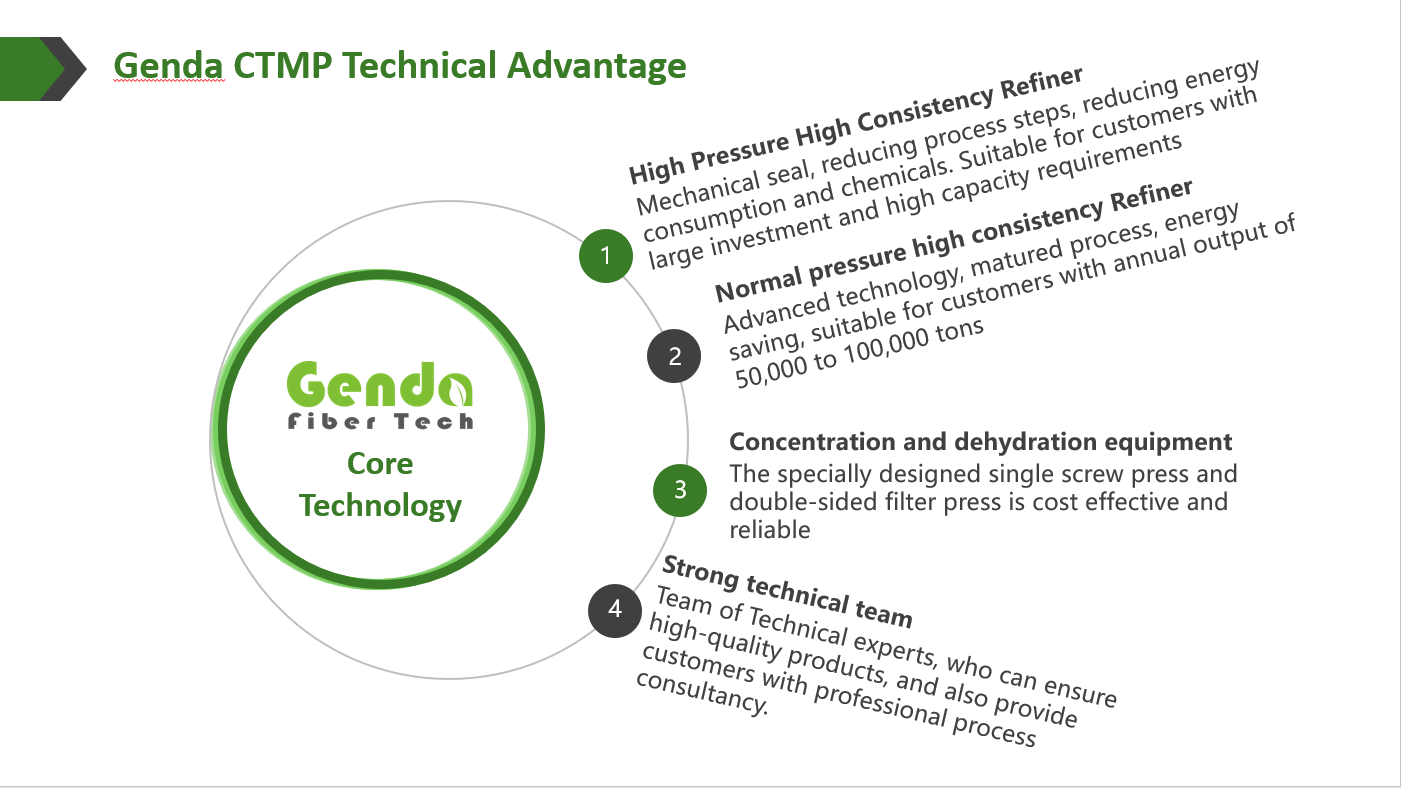

Energy saving, power consumption /ton pulp only 400-800 kwh

Less staff needed, only 1-2 personal required during operation

Less chemical usage, only 80kg-100kg/ton pulp consumption

Diversified raw material Intake: Can be adapted to the production of different raw materials

Flexible in Production: Different pulps can be produced by changing chemicals & dosage along with distribution and refining energy selection. Production capacity can be adjusted from 50T/d to 750T/d

Energy Saving: The high-temperature pressure refiner directly replaces & integrate the wood chip shredder, saving energy consumption of 350kwh/t-400kwh/t

Wood chip washing: cleanliness 90% (no obvious attachments after washing)

Pre-steaming bin: temperature above 90⁰C, time: 20-30 minutes

Cooking section:

The amount of alkali used for cooking: 8-12%

Cooking liquid ratio: 1:4

Cooking temperature: 90 ⁰ C

Cooking pressure: normal pressure

Cooking time: 30-40 Min

Refining section:

Refining concentration: 30-35%

Disc gap: Onsite setting(varies on each application)

Energy consumption of HC refiner: 200-300KWH/odt

Energy consumption of LC refiner: 100-200KWH/odt

Refiner operating power: ≤60% installed power

Pressure filter section:

Screening concentration: 1.2-2

feeding pressure: 2.0-4.0bar, pressure difference between inlet and outlet is not more than 50kpa

Production capacity: 300t/d (screening area 4 m²)